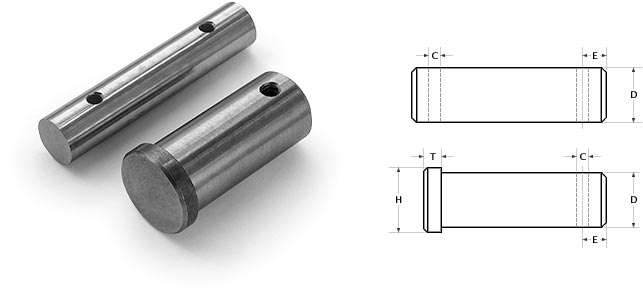

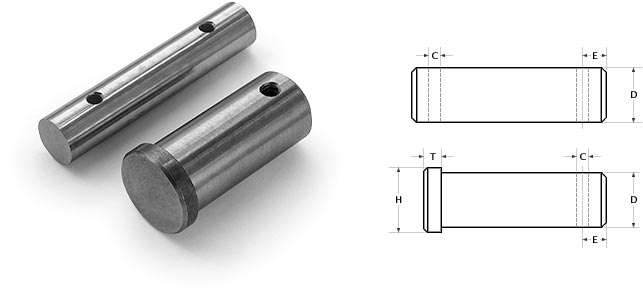

pins

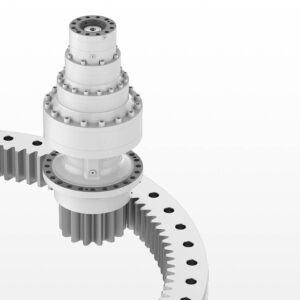

Structural pins are integral components in the construction of marine cranes, serving as key elements that connect and support various structural components. These pins are designed to withstand the dynamic loads, corrosive marine environment, and operational stresses associated with crane operations. Here’s a brief description of structural pins used in marine cranes:

- Material Selection: Structural pins for marine cranes are typically made from high-strength materials to ensure they can withstand the heavy loads and dynamic forces involved in lifting operations. Common materials include alloy steels or corrosion-resistant alloys, providing durability and strength.

- Corrosion Resistance.

- Precision Machining.

- Load-Bearing Capacity.

- Securing Mechanisms: Depending on the crane design, structural pins may incorporate securing mechanisms such as locking devices, nuts, or cotter pins. These mechanisms prevent unintended disassembly and enhance the overall safety of the crane structure.

- Ease of Installation and Maintenance: Structural pins are designed for ease of installation and maintenance. This facilitates assembly and disassembly during construction, maintenance, or repairs, allowing for efficient and timely servicing of the crane.

- Fatigue Resistance.

In summary, structural pins for marine cranes are robust, corrosion-resistant components that play a critical role in maintaining the structural integrity and operational safety of the crane. Their design emphasizes high strength, precision, ease of installation, and resistance to environmental factors, ensuring they can effectively support the loads and endure the rigors of maritime lifting operations.

Reviews

There are no reviews yet.